ASTMB163 ASTMB167 Inconel600/UNS N06600/ 2.4816/NCF600 Seamless Nickel Chromium Alloy Pipe

① STANDARD: ASTM B163/ASME SB163,ASTM B167 / ASME SB167....② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Inconel600/UNS N06600/ 2.4816/NCF600 Chemical Composition

|

Ni |

Cr |

Fe |

C |

Mn |

S |

Si |

Cu |

|

≥72.00 |

14.00-17.00 |

6.00-10.00 |

≤0.15 |

≤1.00 |

≤0.015 |

≤0.50 |

≤0.50 |

Inconel600/UNS N06600/ 2.4816/NCF600 Mechanical Properties

Tensile Strength

≥550Mpa

Yield Strength

≥205Mpa

Elongation

≥35%

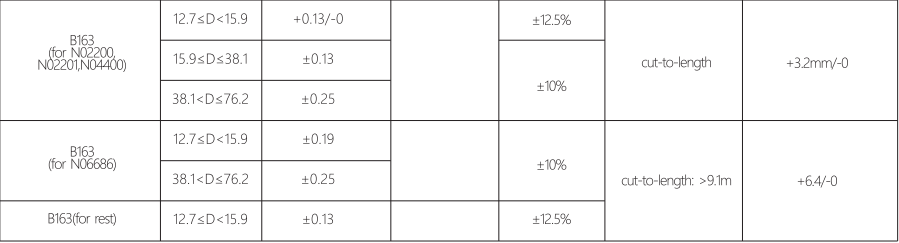

the ASTM B163 Nickel alloy seamless tube and pipe tolerance

Inconel600/UNS N06600/ 2.4816/NCF600 Applications

-

- Heat exchangers

- Furnaces

- Exhaust liners for aircraft

- Production of caustic alkalis

- Chemical and food processing equipment

- Condensers

- Evaporator tubes

- Thermocouple sheaths.

- Ethylene dichloride (EDC) cracking tubes.

- Conversion of uranium dioxide to tetrafluoride in contact with hydrofluoric acid.

- Production of caustic alkalis particularly in the presence of sulfur compounds.

- Reactor vessels and heat exchanger tubing used in the production of vinyl chloride.

- Process equipment used in the production of chlorinated and fluorinated hydrocarbons.

- Furnace retort seals, fans, and fixtures.

- Roller hearths and radiant tubes, especially in carbon nitriding processes.

- Heat treating muffles and retorts.

- Vacuum furnace fixtures.

- Chlorination equipment to 1000 °F.

- Titanium dioxide plants.

- Nuclear reactor vessels and heat exchanger tubing

- Chemical processing equipment

- Heat treat furnace components and fixtures

- Gas turbine components including jet engines

- Electronic parts

- ...........

Standard

|

Pipe - Seamless |

ASTM B167, ASME SB167 |

|

Pipe - Welded |

ASTM B517, ASME SB517 |

|

Tube - Seamless |

AMS 5580, ASTM B163, ASTM B167, ASME SB163, ASME SB167 |

|

Tube - Welded |

ASTM B516, ASTM B751, ASME SB516, ASME SB751 |

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ......

One of our Services--End of Pipe and Tube

- BE : Beveled end

- BBE : Bevel both ends

- BLE : Bevel large end

- BSE : Bevel small end

- TOE / POE = Treaded One End / Plain One End

- TOE / BOE = Treaded One End / Beveled One End

- POE / BOE = Plain One End / Beveled One End

- TBE = Treaded Both Ends

- PBE = Plain Both Ends

One of our Services--Packing

- Ply Wooden Boxes

- PE Fabric Bundles

- Standard seaworthy export packing

- Plastic Bags, or as required

One of our Services--Marking

- Supplier / Manufacturer Name or Custom Logo - on request

- Specification

- Material Grade

- Nominal Size

- Schedule or Wall Thickness

- Method of Manufacturing (Seamless or Welded)

- Heat Number

Marked Pipe Sample: XTD ASTM B167 UNS N06600 SEAMLESS 42.2x 3.56*6000MM HEAT NO. 2023121205A15

Inconel600/UNS N06600/ 2.4816/NCF600 Material Summary

Nickel Alloy 600, also sold under the brand name Inconel® 600. It is a unique nickel-chromium alloy that is known for its oxidation resistance at higher temperatures. It is highly versatile and can be used in everything from cryogenics to applications that present elevated temperatures up to 2000°F (1093°C). Its high nickel content, a minimum of Ni 72%, combined with its chromium content, provides users of Nickel Alloy 600 a number of benefits including:

- Good oxidation resistance at high temperatures

- Corrosion resistance to both organic and inorganic compounds

- Resistance to chloride-ion stress corrosion cracking

- Works well with most alkaline solutions and sulfur compounds

- Lower rate of attack from chlorine or hydrogen chloride

Its chromium content gives the alloy resistance to sulfur compounds and various oxidizing environments. The chromium content of the alloy makes it superior to commercially pure nickel under oxidizing conditions. In strong oxidizing solutions, like hot concentrated nitric acid, 600 has poor resistance. Alloy 600 is relatively unattacked by the majority of neutral and alkaline salt solutions and is used in some caustic environments. The alloy resists steam and mixtures of steam, air, and carbon dioxide.

Alloy 600 is non-magnetic, has excellent mechanical properties and a combination of high strength and good workability and is readily weldable. Alloy 600 exhibits cold forming characteristics normally associated with chromium-nickel stainless steels.

Typical corrosion applications include titanium dioxide production (chloride route), perchlorethylene syntheses, vinyl chloride monomer (VCM), and magnesium chloride. Alloy 600 is used in chemical and food processing, heat treating, phenol condensers, soap manufacture, vegetable and fatty acid vessels and many more. Link to alloy 601 that was developed to be more resistant to high-temperature oxidation than alloy 600.

Standard download

Related Products

ASTMB163 ASTMB167 Inconel600/UNS N06600/ 2.4816/NCF600 Seamless Nickel Chromium Alloy Tube

① STANDARD: ASTM B163/ASME SB163,ASTM B167 / ASME SB167....② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

ASTMB983 Incoloy925 Alloy925 UNSN09925 2.4858 Seamless Nickel Alloy Steel Tube

① STANDARD: ASTM B983...② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

ASTMB165 Monel 400/Alloy400/UNSN04400/2.4360 Seamless Nickel-Copper Alloy Steel Pipe

① STANDARD: ASTM B165 ...② OD RANGE : 6-457 MM③ THICKNESS RANGE: 1-45 MM

Hastelloy C-4 2.4610 NiMo16Cr16Ti N06455 Seamless Stainless Steel Tube

Alloy C-4 / 2.4610 is an austenitic low-carbon nickel-molybdenum-chromium alloy① STANDARD: ASTM B161/ ASTM B163/ ASTM B167/ ASTM B444/ ASTM B622 ...② OD RANGE : 6-257 MM③ THICKNESS RANGE: 1-35 MM

Online Inquiry

If you have any enquiry about quotation or cooperation,please feel free to email us at admin@xtd-ss.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.